The access door and main guard have safety switches to prevent the machine operating if either are open. The system is monitored using a dedicated safety relay. All moving parts are guarded.

The machine is designed to be a cost effective unit requiring the minimum of operator intervention. The 9” colour touch screen interface allows the operator to program their required core lengths.

The core is indexed forward to the new cut position using a high precision ball screw with servo control of the indexing. This allows movement to micron accuracy. Unlike belt driven systems, the accuracy does not diminish with time.

The machine base is a fabricated steel structure that is very rigid. The machine is very strong and has been designed for a long life with the minimum of maintenance.

The core is drawn into the machine and the length of the core is measured automatically before the core cutting sequence begins.

Maximum cutting speed of 60 Cores per minute (Dependant on core material and cut width). The speed of rotation is automatically set to keep the optimum surface speed to obtain a clean cut.

The machine senses when the blade has cut through the core and the blade is automatically retracted to maximise the blade life.

The servo positioning system advances the core under the knife. If selected, an initial trim is taken to clean up the edge of the core, then the required core lengths are produced.

The machine has an adjustable core loading support to assist with loading the parent core into the machine.

The rollers that support the core during the cutting process are automatically positioned at the correct height to suit the core being processed. There are no adjustments for the operator.

The machine senses the speed of the cut and changes the pressure to keep the speed of cut constant. This Dynamic Cut Pressure system ensures that the cutting time is maintained as the blade ages.

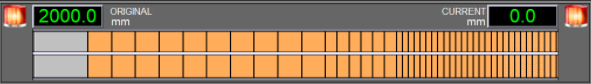

Once the core has been measured, the Core-Miser system works out the optimum cut sequence to minimise any waste. A graphical representation of the cut sequence is shown on the display. This is dynamic so you can see the progress of the cutting operation.

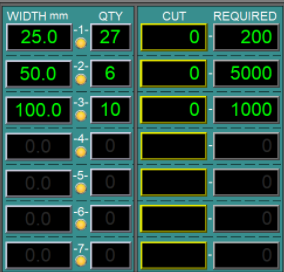

The option for variable core lengths is built into the CCA machine as standard. Up to 7 different lengths can be programmed to be cut.

When a cut sequence is programmed, a visual representation of the cut sequence is shown on the touchscreen. This is dynamic, changing as each core is cut.

| Feature | Imperial | Metric |

|---|---|---|

| Cutting mandrels available for core ID | 2 3/4" 3" 4" 5" 6" 6.75" | 70mm 76mm 102mm 127mm 150mm 152mm 167mm |

| Maximum core length options | 86" 137" | 2200mm 3500mm |

| Maximum cutting speed | 60 cores per minute | Dependant on core material and cut width |

| Maximum core wall thickness | 0.8" | 20mm |

| Cut length accuracy | +/- 0.1mm | |

| Minimum | 1/6 inch | >4mm |

| Core material | Cardboard Paper Plastic |

Request a Quote for the CCA Core Cutter

Interested in the CCA Automatic Core Cutter? Fill out the form below to discuss your specific requirements.