Hot Melt Coaters

From compact in-line coating stations to wide-web laminators, our hot melt coating machines are designed for precision, performance, and reliability. Find the right solution for your specific application.

HMCS – Hot Melt Coating Station

Allows printers to coat hot melt adhesive in-line on their print presses, enabling them to service customers requiring adhesive coating without incurring the costs associated with installation of a dedicated line.

- In-line hot melt coating on print presses

- Continuous, striped, or patch coating

- Supports pressure sensitive, heat seal, and UV curing adhesives

- Motorised adjusting system for precision

CL350 Narrow Width Hot Melt Coater Laminator

A compact, narrow-width machine for testing or production, featuring precise tension and adhesive control systems typically found on larger machines.

- Speeds up to 200 m/min

- Wide range of coat weights (1-500 gsm)

- Processes non-woven, paper, and plastic materials

- Multiple coating technologies available

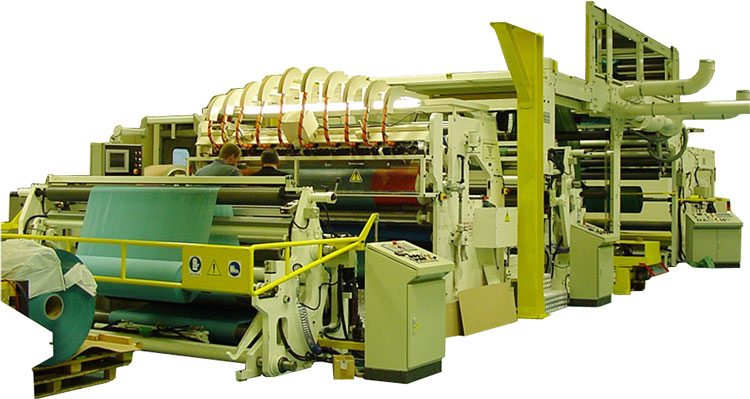

CL1600 Hot Melt Adhesive Coater Laminator

A wide web machine suitable for high-speed production, available in several configurations with options like turret unwind/rewind systems for non-stop operation.

- 1600mm maximum web width

- High speeds up to 250 m/min

- Proximity slot dies or non-contact spray tech

- Turret systems for continuous production

Non-wovens Coating Solutions

Purpose-designed coater laminators for the non-wovens industry, utilizing advanced hot melt fiberisation technology for superior performance.

- 25 years of experience in non-wovens

- Advanced fiberisation technology

- Speeds up to 450 m/min

- Web widths up to 4m

Dynafiber UFD

Patented application technology for high-speed lamination of non-woven and other substrates at very low hot melt adhesive coat weights, maintaining breathability.

- Coat weights below 1gsm

- Speeds up to 1000 m/min

- Maintains substrate breathability

- Modular design for easy expansion

Slot Die Coating Systems

We offer a range of specialized slot die coating systems from leading manufacturers to meet diverse hot melt adhesive application requirements.

- Continuous and intermittent coating

- Wide and narrow web applications

- Variety of adhesive viscosities

- High precision and reliability