| X | Y | |||

|---|---|---|---|---|

| Roll diameter options: | ||||

| 12 inches | 300mm | 3400mm | 2500mm | |

| 24 inches | 600mm | 3600mm | 2700mm | |

| 32 inches | 800mm | 3800mm | 2900mm | |

| 40 inches | 1000mm | 4000mm | 3100mm | |

| 60 inches | 1500mm | 4200mm | 3300mm | |

| Web width options: | ||||

| 12 inches | 300mm | 3000mm | 2100mm | |

| 24 inches | 600mm | 3200mm | 2300mm | |

| 32 inches | 800mm | 3400mm | 2500mm | |

| 40 inches | 1000mm | 3600mm | 2700mm | |

| Speed options: | ||||

| 1000 ft / minute | 300 m / minute | |||

| 1500 ft / minute | 450 m / minute | |||

| 2000 ft / minute | 600 m / minute |

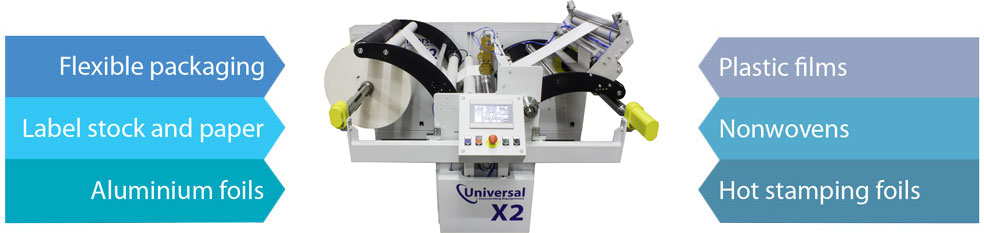

Request a Quote for the Salvage Rewinder X2

Interested in the X2 Salvage Rewinder? Fill out the form below and one of our specialists will get back to you shortly.